Delft University of Technology

Sep - Oct 2024

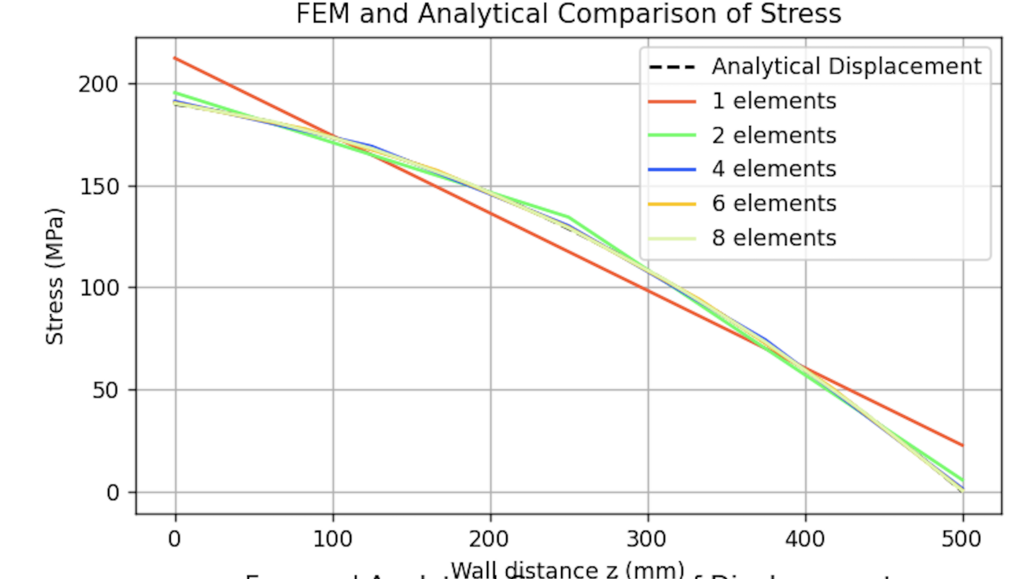

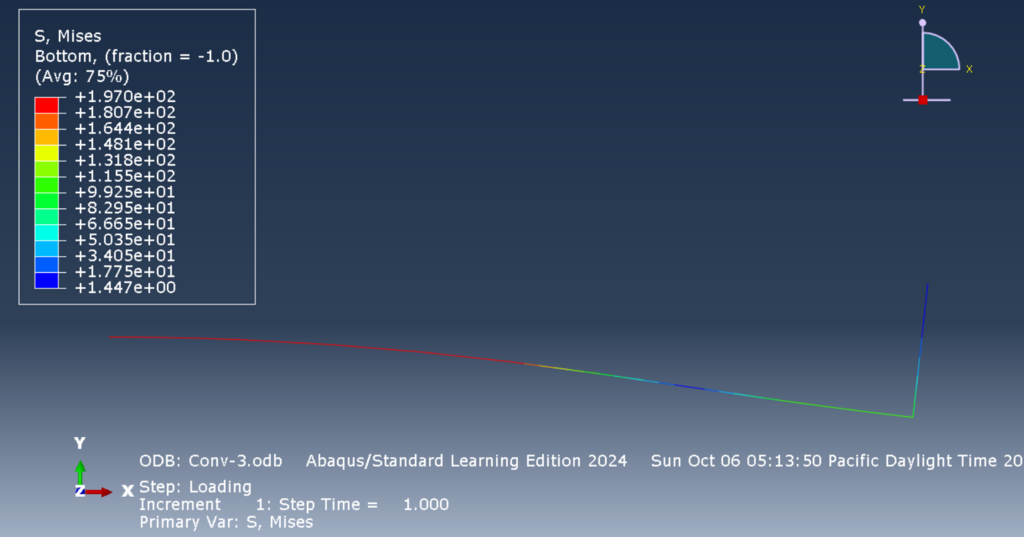

Purpose: To find the optimal number of elements to model Ingenuity helicopter blades. To optimize the rover beam for weight and strength under worst loading conditions.

Please feel free to check out the Python code on Github: https://github.com/NilgunAbali/IngenuityFEM

• Derived analytical and FEM equations for Ingenuity rover helicopter blades under linearly-varying centrifugal force, modeling them as quadratic bar elements

• Developed custom Python code to solve derived FEM equations for Ingenuity blades, with varying element number

• Performed convergence study to identify optimal number of elements, and conducted a normalized RMSE comparison between analytical and FEM solutions, visualizing results on Python

• Modeled structural response of Ingenuity helicopter’s supporting beam under worst-case loading conditions in Abaqus, optimizing for lightest structure by selecting appropriate materials and cross-sectional geometries

Fig. Ingenuity Rover

Fig. Stress Convergence Study using Python

Fig. Weight Optimization using Abaqus

UBC Agrobot

May - Aug 2024

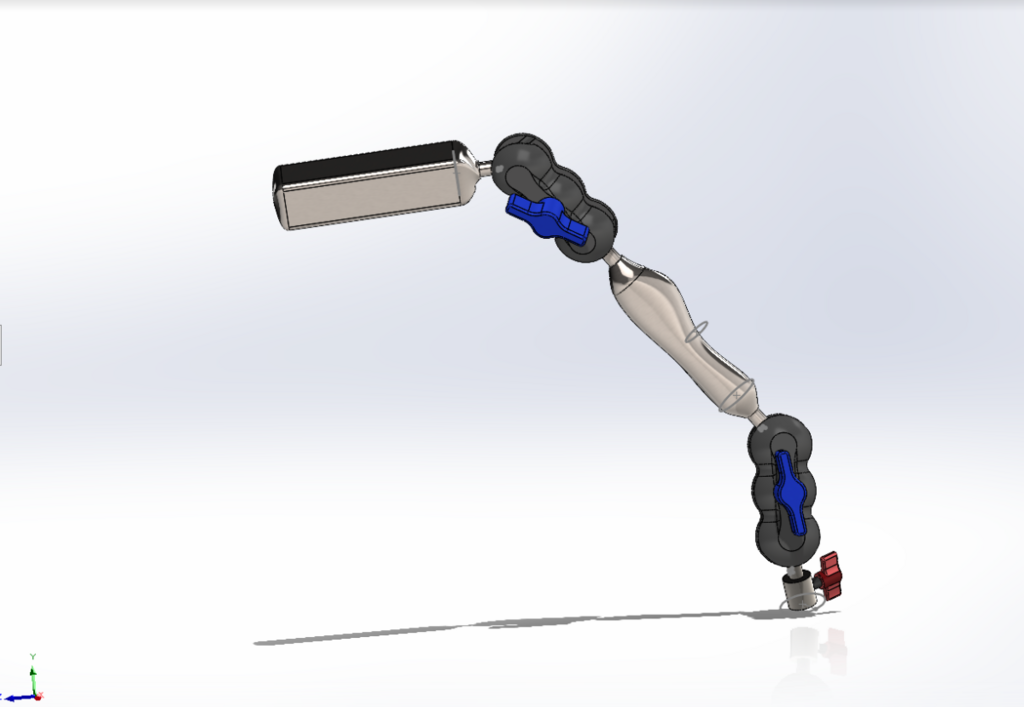

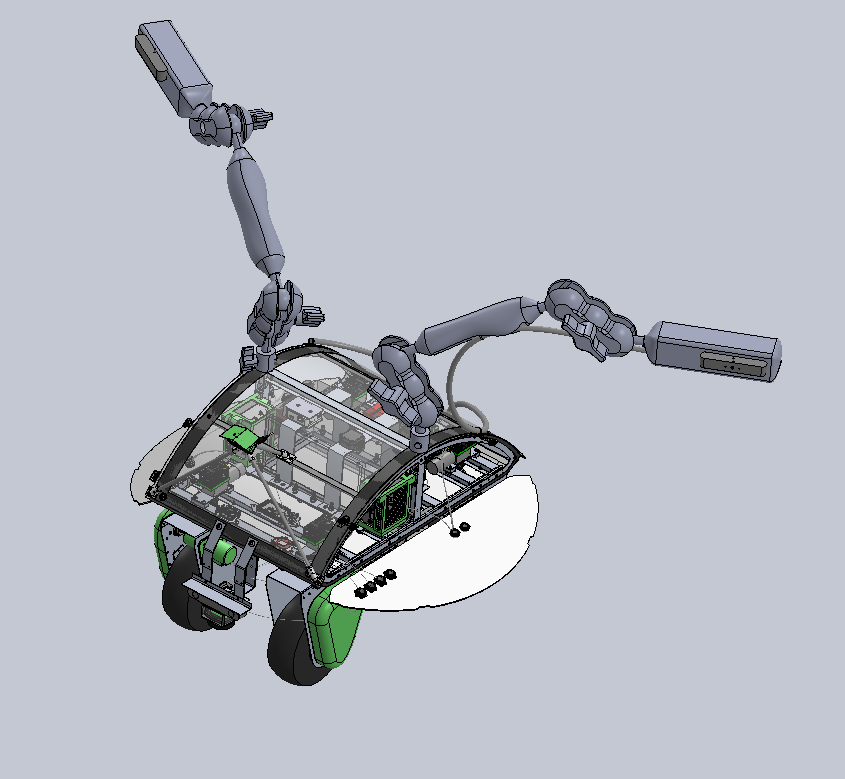

Purpose: To design a mechanical structure that extends from the robot, carries the weed extermination system

Please feel free to check out the CAD at: https://github.com/NilgunAbali/WeedExterminatorArm

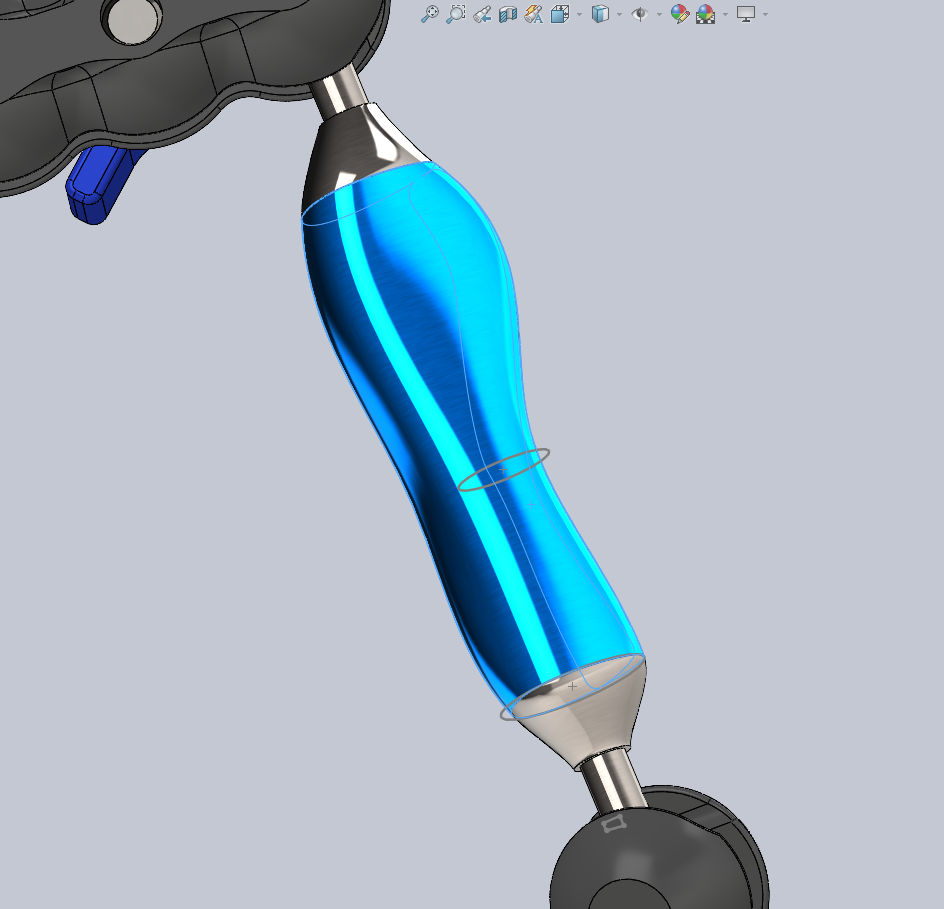

• Engineered a robotic arm with 6 DoF using SolidWorks, integrating organic shapes while adhering to 3D printing design and DFA principles

• Spearheaded and managed a 10-step testing process for pump and electric circuits to optimize performance and identify critical parameters such as working pressure, flow rate, and spray range

Fig. Exterminator Arm CAD in SolidWorks

Fig. Organic Structures within Arm

Fig. Extermination Arm Assembled with Robot Body in SolidWorks

University of British Columbia, Pulp and Paper Center

Jun - Jul 2023

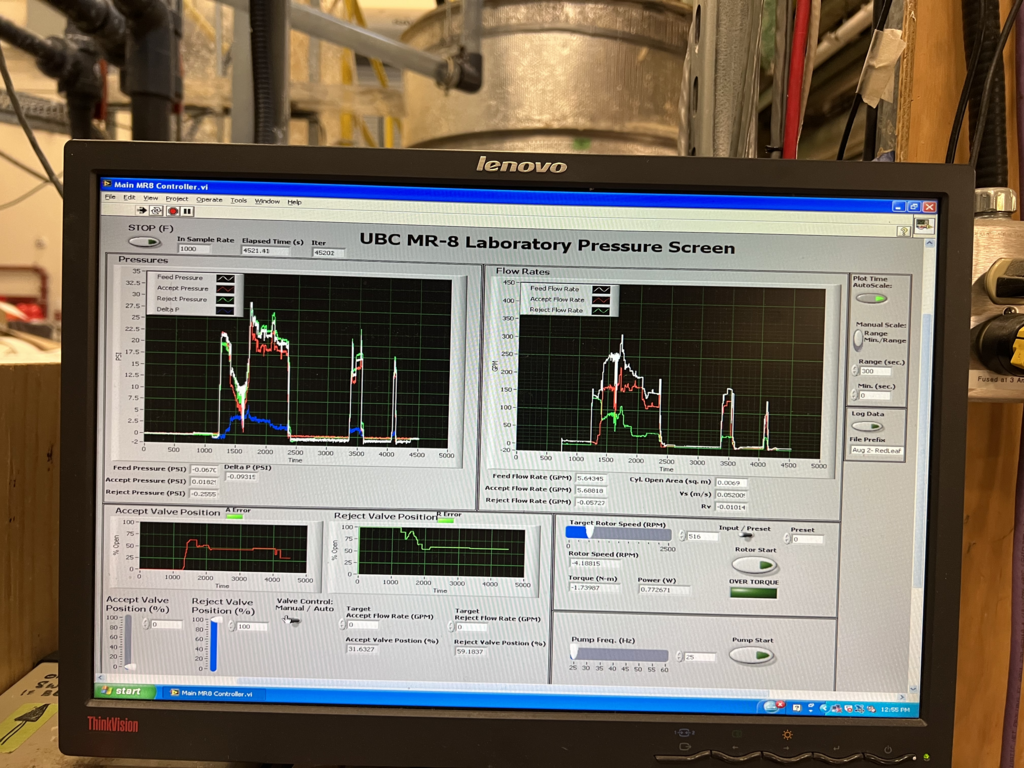

Purpose: Run a pilot wheat straw screening operation to find optimal operational parameters and present the data to industry professionals

• Analyzed raw sensor data from LabView to create graphical representations of mass flow, volumetric flow, and shive percentage using MATLAB and Excel, ultimately determining the optimal pulp screening run conditions

• Troubleshot screen failure during pilot operation by recycling pulp and adapting conservative flow rates, saving 2 weeks of logistical work for team

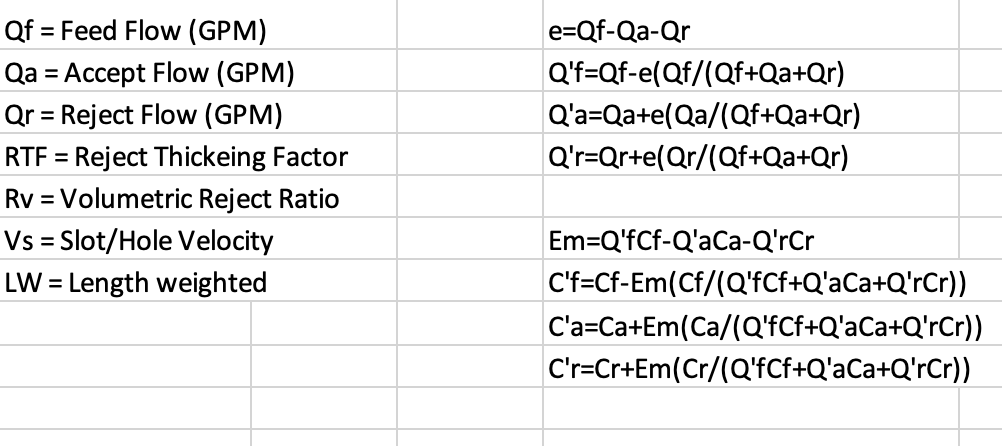

• Derived mass flow balance equations to convert LabView sensor data into meaningful insights into input and operational run conditions

Fig. Pulp Screener

Fig. Raw Sensor Data Acquired from LabView

Fig. Derived Mass Flow Balance Equations

University of British Columbia,

Mar - Apr 2024

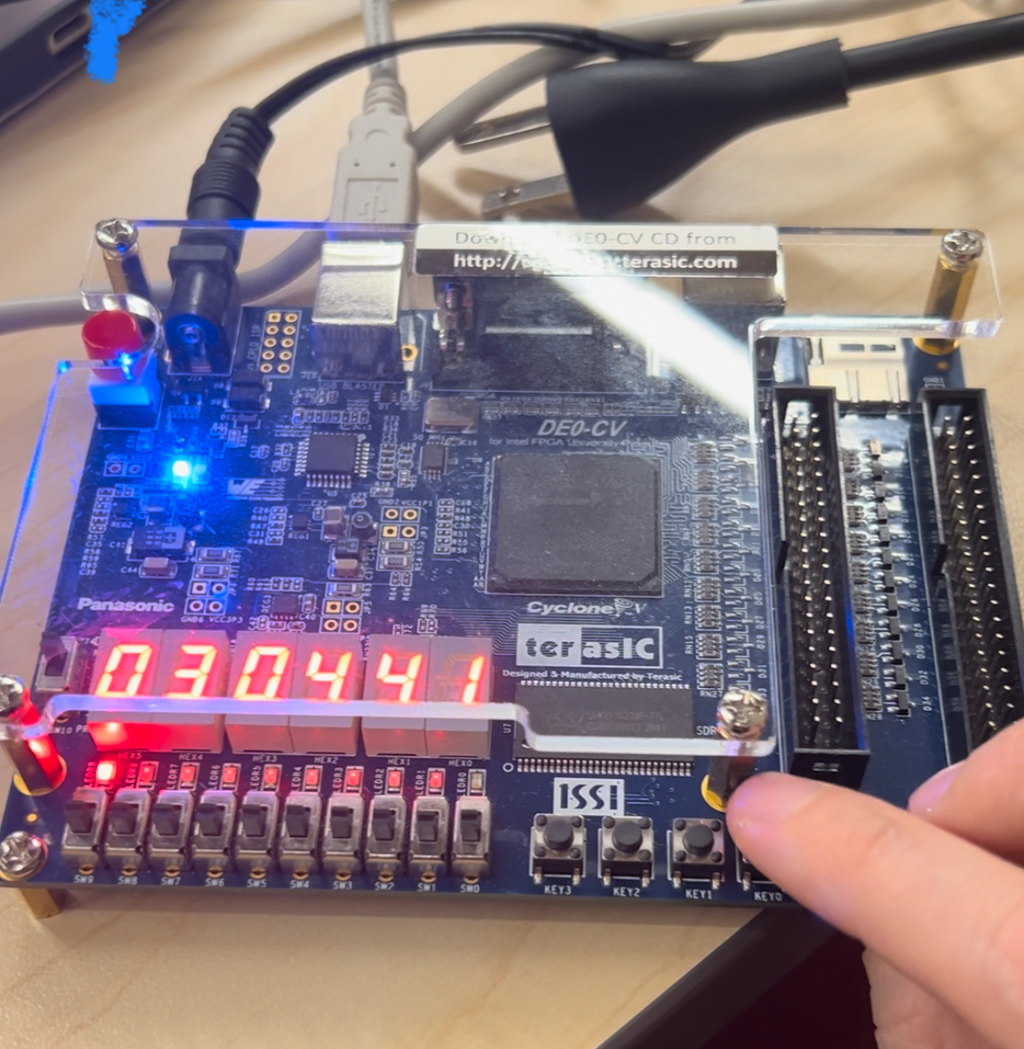

Purpose: Program the DE0-CV board to display an alarm clock and activate an LED when the alarm time is reached. Program the DE0-CV to accept BCD inputs for performing addition, subtraction, multiplication, division, and BCD addition.

See what projects I have done on DE0-CV: https://github.com/NilgunAbali/DE0-CV

•Coded in Assembly language to accept binary inputs from switches, interpret them as BCD, store the data in registers, and use latches for calculations and final display of the calculation

•Described the alarm clock circuit using VHDL in Quartus Prime and coded in Assembly to operate on a 12-hour system, accepting binary inputs for hours, minutes, and seconds.

Fig. De0-CV programmed as alarm clock taking inputs

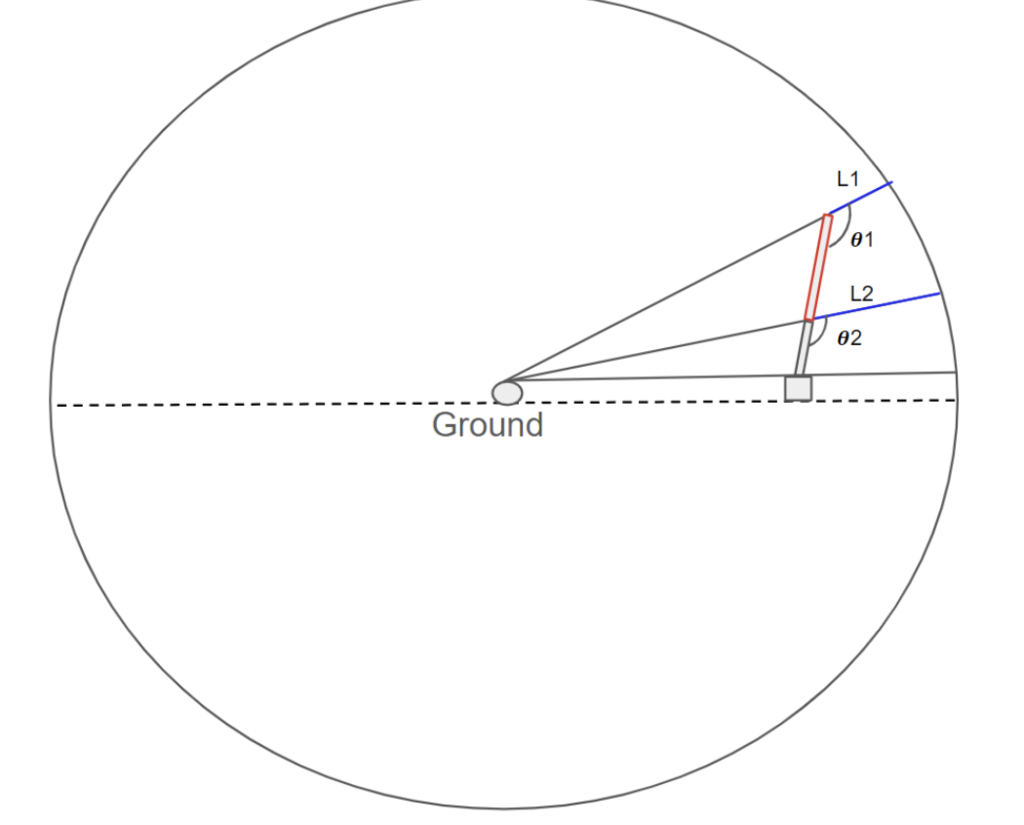

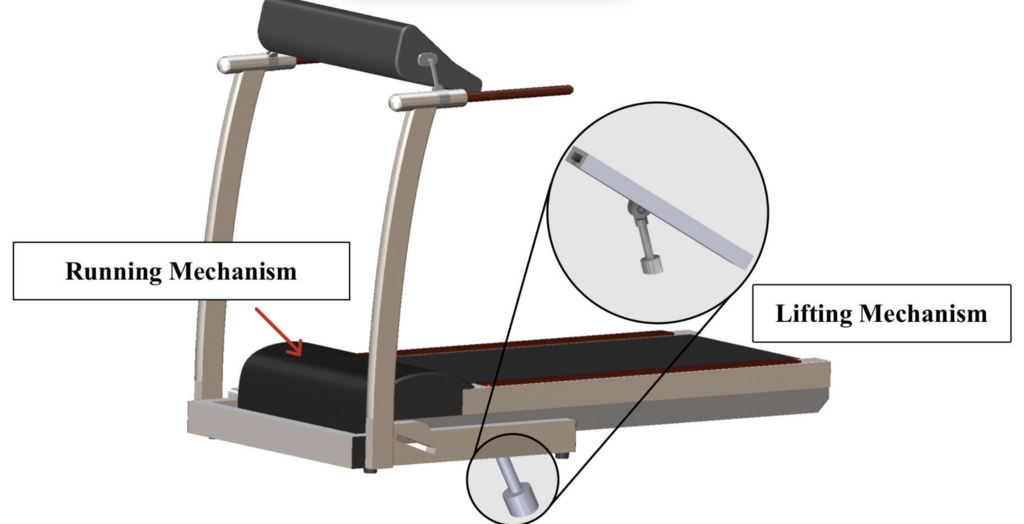

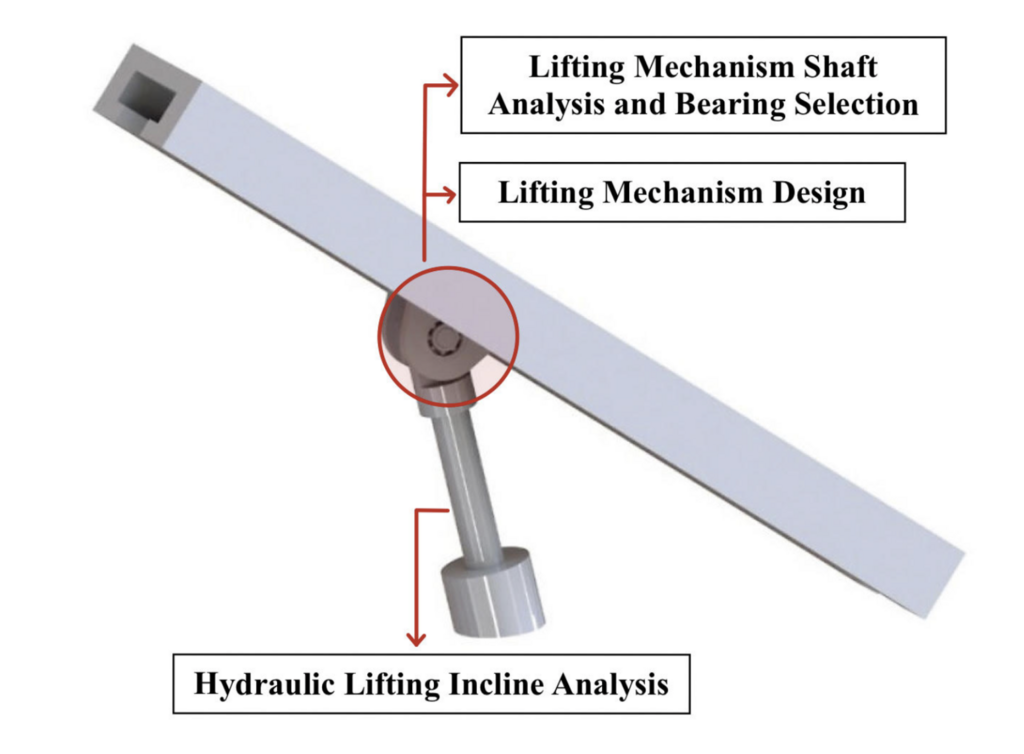

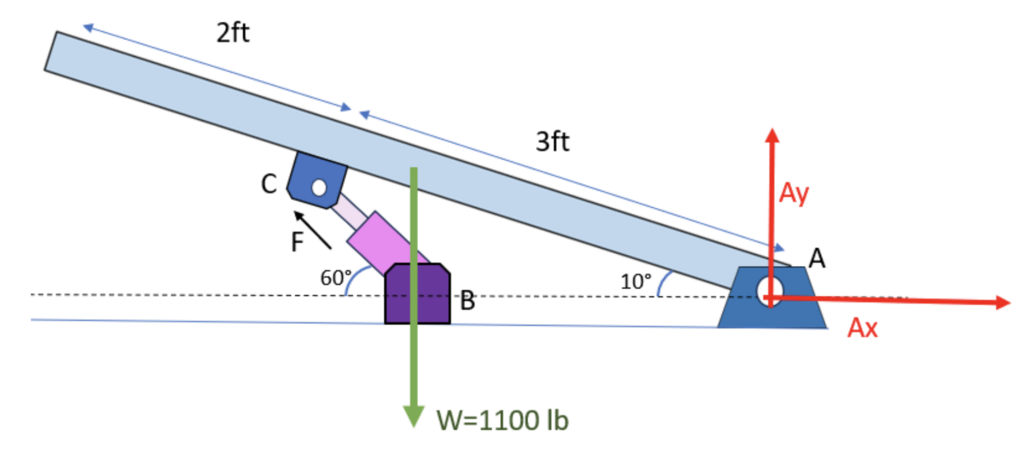

Purpose: Collaborate with a student team to utilize a machine design process to develop a treadmill with adjustable incline features.

•Established the treadmills's lifting mechanism parameters by determining incline, safety factor, and working pressure based on stakeholder research and trigonometric calculations

•Performed detailed calculations, determining rod and bore dimensions, lifespan, and hydraulic force using Shigley's machine design process

•Selected an optimal motor, choosing a 7HP, 3-phase motor capable of delivering 1200lbf lifting force at a 10% incline, with lifting speed of 2in/sec and a projected lifespan of 10 years

Fig. Various inclines' contact angle diagram

Fig. Final Treadmill Design

Fig. The CAD model for the final lifting mechanism

Fig. Freebody Diagram of the Lifting Mechanism

University of British Columbia

Jan - May 2023

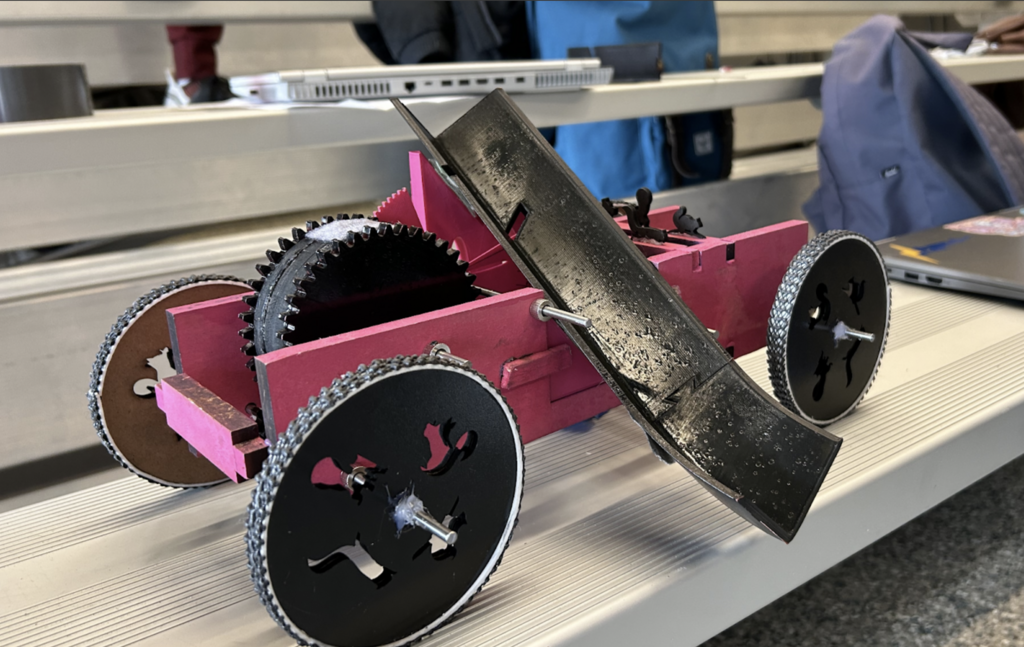

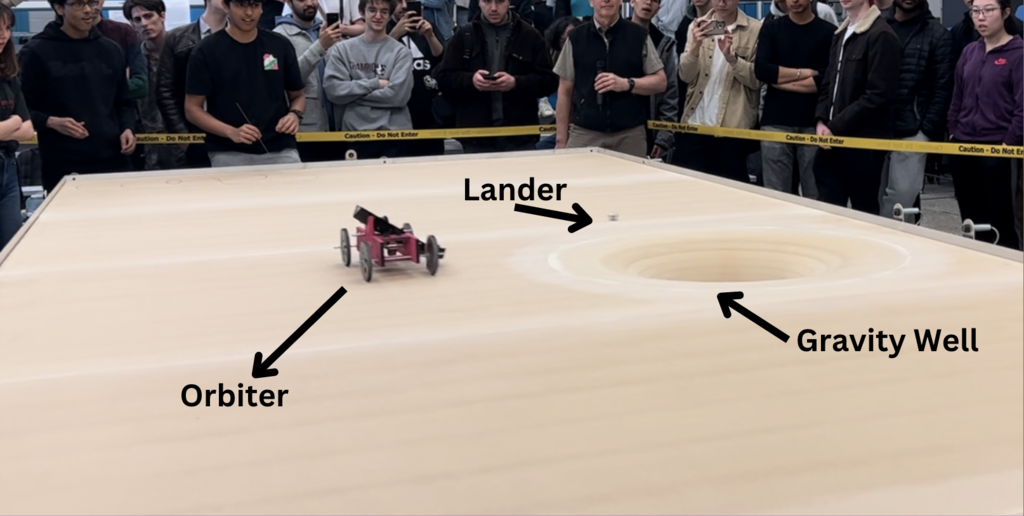

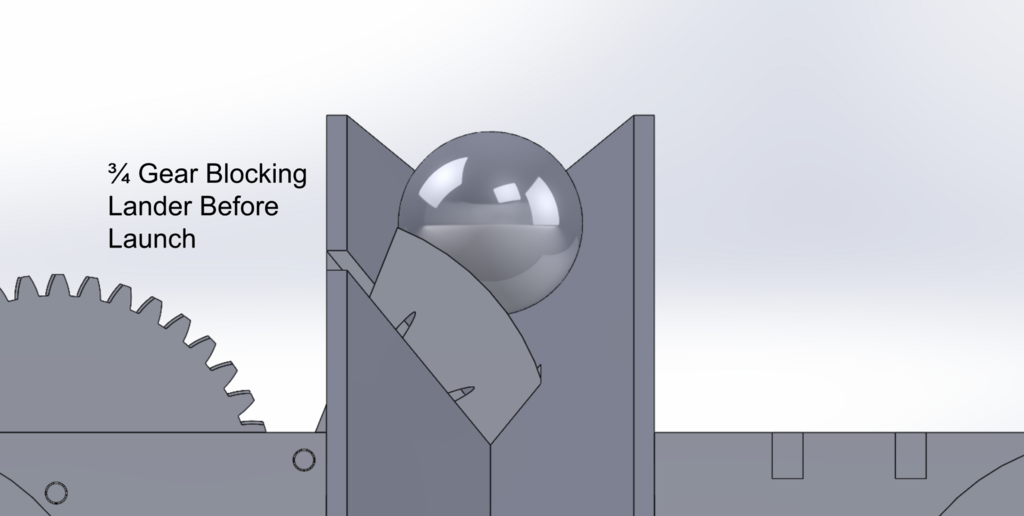

Purpose: The Titan Endurance Project tasks teams with re-creating a simplified versionof the launching, orbiting, and landing of a probe on Titan's surface.

Applied a comprehensive mechanical engineering design process, encompassing concept generation, evaluation, selection, prototyping, and selection

Refined skills in machining, hand tools, power tools, and DFM principles by constructing the orbiter's chassis, axles, and launching mechanism hands-on

Troubleshot design challenges, including adding a rubber layer to the wheels of the orbiter, which reduced slippage by 90%

Fig. Final Orbiter Design

Fig. The Competition Gravity Well

Fig. All Mechanical Lander Launching Mechanism

Vancouver, BC

Jan 2023

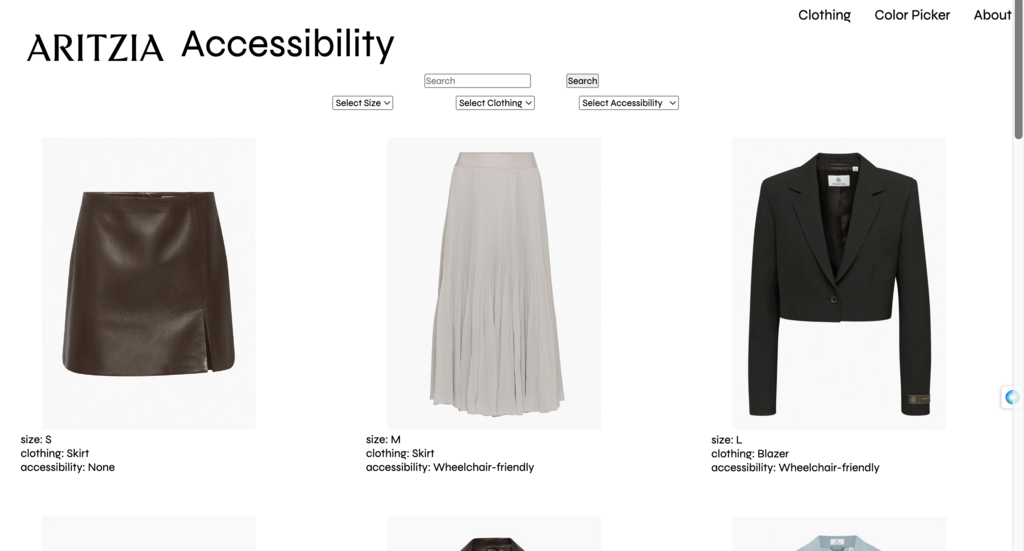

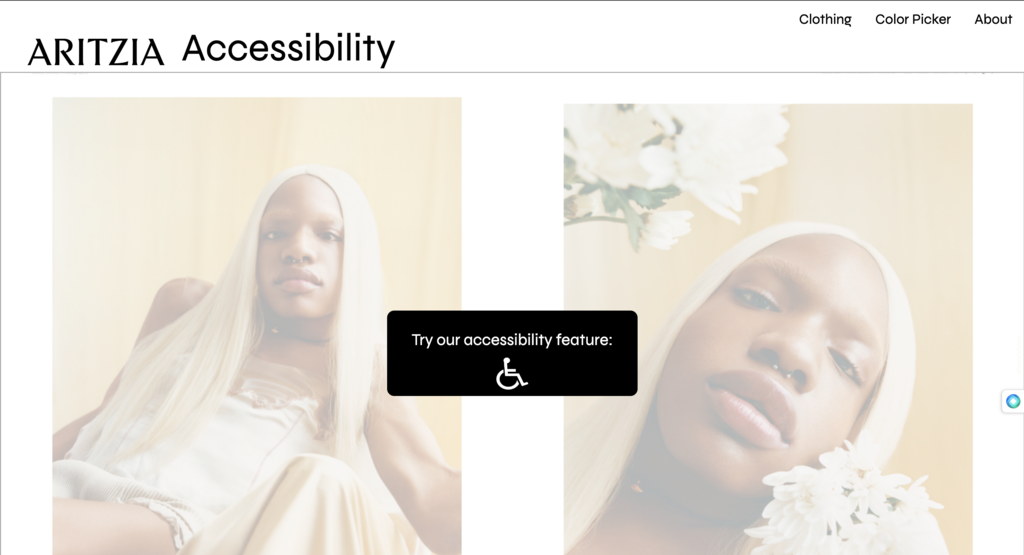

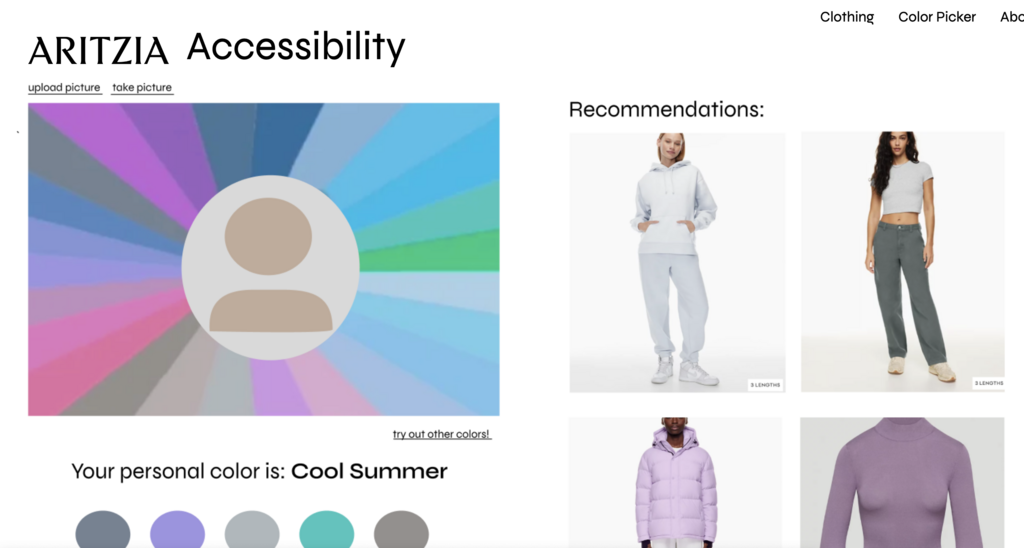

Hackathon Case Problem: How can we use technology to personalize fashion-retail while enhancing e-commerce experience?

Less than 2 days, we designed a website that enhances the e-commerce experience of wheelchair users by increasing wheelchair accessibility and furthermore, to help people find a color palette that will fit them.

Won The Most Creative Hack and The Best Beginner Hack awards as a result of our team’s intensive teamwork

Please check out our website in DevPost: https://devpost.com/software/aritzia-accessibility?ref_content=user-portfolio&ref_feature=in_progress

Inspiration: Tiktok content creator Samantha Jade Durán, who advocates for wheelchair-friendly accessibility in fashion.

What it does: Filters clothes that are wheelchair-friendly and creates a personal color palette.How we built it:Using replit.com, main coding languages were done with HTML, CSS, JavaScript. US/UX design was first done on Figma.

Challenges we ran into: Everyone's first time coding in HTML, CSS, and JavaScript. Lack of experience and time.

What we learned: Patience is important! And learning three new languages in two days is not impossible.

What's next for Aritzia Accessibility: Create more filters, add the entirety of Aritzia's clothing line, and implement a fully functional color picker.

Fig. Accessibility Filter

Fig. Aritzia Accessibility Main Page

Fig. About Page

Fig. Color Picker Feature of our Website